For nearly 20 years, Microfluidics has been heralded as a game-changer in almost every industry, particularly in the life science industry. However, despite having so much work done in the last decade, it is still considered “immature” for certain applications. The research in the last few years has led to devices now capable of outdating their previous models and have a great potential in addressing some of critical challenges in science. Before we look into the life journey of this technology until now, it is important to understand the phenomena and effects that dominate the behavior of mixtures and liquids. An in-depth understanding of Microfluidic Technology will help in understanding the advantages of Microfluidics, such as simpler kinematics and faster reaction times.

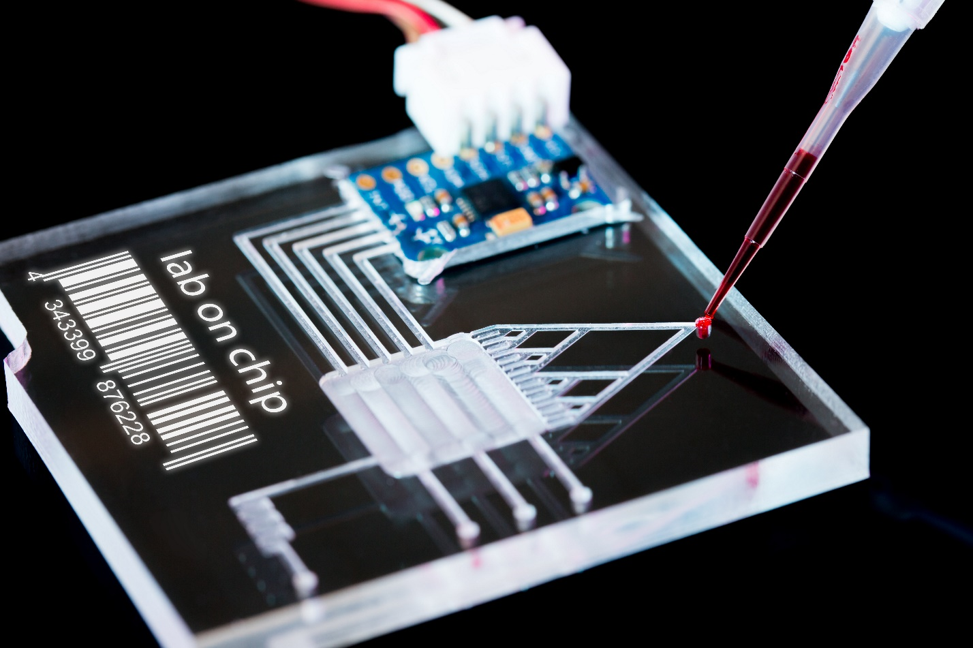

A microfluidic system is a fluidic device engineered to provide a non-turbulent flow in a highly ordered manner. Normally, this overlaps with the device dimensions in the order of tens to hundreds of micrometers. The term “microfluidic” defines a technique that has increased its influence from its early application in ink-jet printing and analytical science to problems that are far more complex and novel. Today, microfluidic devices are used in ultra-high-throughput biological analyses or in the simulation of an entire organ system.

All early predictions regarding the potential of new technologies are often unreliable and turn out to be incorrect. This is often due to the fact that if a technology is not a stand-alone product but an enabling set of techniques, predictions about its future are almost impossible to make. The Survey of some of the notable literature has validated the impression that microfluidic devices or technologies are being used extensively as a key component in basic science applications. According to other assessment reports, microfluidic technology is being used extensively in different areas of science and often to enhance the performance of existing protocols or to completely replace them with its superioir characteristics.

In the beginning of 2014, a researcher Dr. Abhiteja Konda under the guidance of Prof. Stephen Morin, both at the University of Nebraska, conducted research on designing and fabricating microfluidic devices using a rather, non-traditional approach which ultimately lead to the invention of microfluidic devices that can be operated on non-planar, three-dimensional (3D) objects. This work titled “Reconfigurable microfluidic systems with reversible seals compatible with 2D and 3D surfaces of arbitrary chemical composition” was published in Lab on a Chip. Their approach is both unique and novel and was based on the idea of using a combination of polymers (polydimethylsiloxaneand Ecoflex®) and “reversible compression-based seals” to seal devices to non-planar surfaces. In this research, Konda along with his team, fabricated, designed, and tested a plethora of devices using multiple support substrates such as gels, plastic, metals, etc. in 2D and 3D geometries (planar, corrugated and curvilinear) and then used these devices for demonstrating capabilities of microfluidic systems with seals created through compression.

Unlike other traditional approaches, this approach helped the devices offer greater flexibility within the network design and achieve better pressures and flow rates. According to Konda, their approach enables easy integration of devices onto various substrates and opens the field to explore a lot of potential applications.

Using their devices, Prof. Morin, Dr. Konda and team explored the areas of nanomaterial synthesis to create hybrid structures, electroless deposition to create copper traces, and soft robotics to integrate sensing capabilites. These demonstrations are only the tip of the iceberg and there is much more to realize in this direction and in many other fields. One of the other major contribution by this group is the invention of a novel, simple, and inexpensive approach to the production of 3D circuits achieved via the seamless integration of microfluidics with various non-planar substrates.

We hope that this brief analysis has helped you understand the possibilities of microfluidic technologies in different industries. At a more fundamental level, it is evident that microfluidic technologies have undergone several significant developments since its first inception in the late 90s. The technology has many other applications that can help us push the boundaries of science into a different dimension. This is not an overnight evolution by any measure, and it is fair to say that majority of literature on microfluidic systems have a strong technological focus and consider microfluidics as a remedy that solves a majority of the current technological issues.